PROTECTION & SAFETY

Where it all began

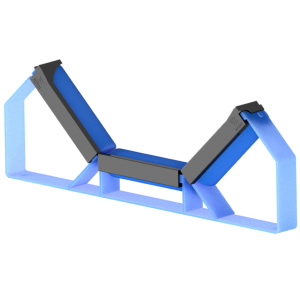

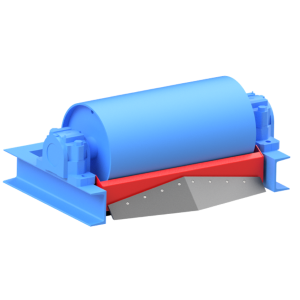

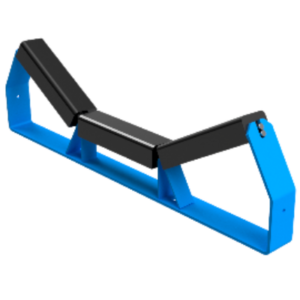

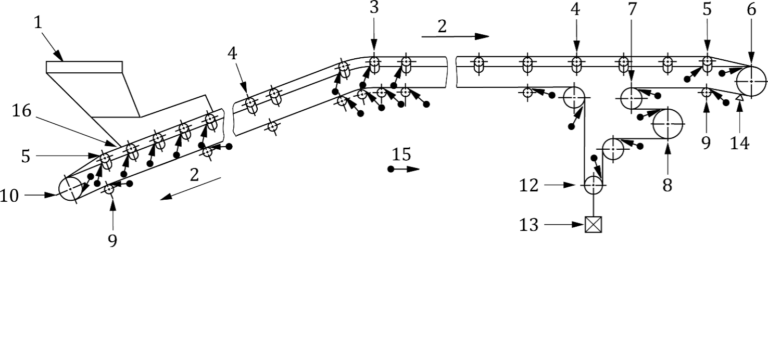

The belt conveyor is a conveyor belt which is constantly supported and driven by idlers rollers. This is widely used in the mining and quarrying industry to transport bulk products at an industrial rate from point A (extraction point) to point B (storage point, factory..).

Its economic and robust aspect, its ease of maintenance as well as its performance explain its democratization in the field.

However, at the time of its establishment, industrial design neglected a fundamental aspect of the design cycle, namely, the analysis of the risks to all labors around the conveyor.

Indeed, the movement of the belt on the rotating rollers intrinsically gives rise to what are commonly called in the middle, re-entrant angles, nip point.

D’aspect inoffensif au premier abord, un simple contact avec une des deux surfaces en mouvement peut risquer d’entrainer de manière inexorable entre les rouleaux et la bande chargée un corps ou objet, risquant l’écrasement, voire l’arrachement…

Au fil des ans, le nombre d’accidents, souvent mortels, provoqués par le convoyeur à bande représentait une statistique alarmante auprès de la CRAMIF.

This is how the regulations around nip angles were written and proposing in his writings the innovative ideas of Mr René Brunone to guarantee the safety of workers in the field.

What does SPAR mean?

S

Safety

P

PROTECTION

AR

NIP ANGLES

La gamme SPAR est principalement destinée pour la sécurité des travailleurs et la mise en conformité centrée sur la protection rapprochées, en supprimant le danger représenté par les angles rentrants, et cela, sans altérer le bon fonctionnement du système initial.