Mid rangeSPARGA

Optimisation & Amélioration

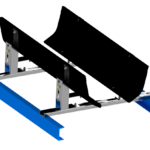

Leak less loading table - SPARGA

The SPARGA eliminates roller stations, metal troughs and traditional flap systems at the loading point of belt conveyors. It prevents material leaks at the loading point and eliminates adjustment and maintenance operations, which are known to be tedious and costly.

- Products Features

- Features

- Video

- The SPARGA is made up of two very resistant Polyspar cheeks supported by adjustable rails mounted on shock-absorbing studs.

- The side rails allow the belt to be raised and form a 75° trough.

- Removal of nip angles at the loading point.

- The SPARGA fixing system allows a simple, fast and precise adjustment.

- Extension of belt life.

- Removal of rubber skirts.

- improving the centering of the belt.

- The SPARGA trough can be used for grain sizes up to 150 mm and head heights of less than 2 m.

- SPARGA is available for belt widths from 500 to 1200 mm.

- The transition and troughing area should be 1.5 to 2 times the width of the belt, depending on belt type and speed.