DEWAG - Unloader on Truck

DEWAG-DchargeurwagonISO

DEWAG 5

DEWAG 2

DEWAG 12

DEWAG 4

DEWAG 10

DEWAG 7

DEWAG 15

DEWAG 8

DEWAG 1

Railway Equipment

DEWAG - Unloader on Truck

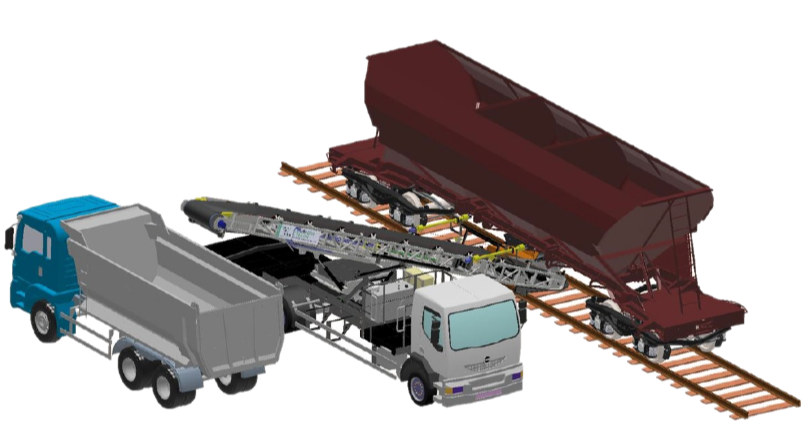

The DEWAG is a truck mounted railcar unloading tool with a swivel, tilt and telescopic toggle. It allows the material (like ballast) to be unloaded and recharged directly on a stock, a truck, or even another train.

- Products Features

- Wagon compatibility

- Video

- 1500 t / h unloading capacity

- Conveyor length: 10.6 m

- Band width 1000/1200 mm

- Belt speed : 3 m/s

- Unloading time 1 train EX 1500 T: 3h

- Conveyor orientation: + / 90°

- Angle inclination : 0 - 30°

- Translatable over 2,4m

- EX type FANPS wagon with 2 or 3 lower exits

- F70 wagon with 3 side exits

- F40 wagon with 2 side exits

- D12 wagon with 3 side exits

- Other wagons on request

The options available for optimal results:

- Truck supllying

- Remote control

- Remote truck maneuver

- Automatic opening of helmets

- Hydraulic hopper sealing

- Hopper unclogging hammer

- Scraper

- Nozzle discharge

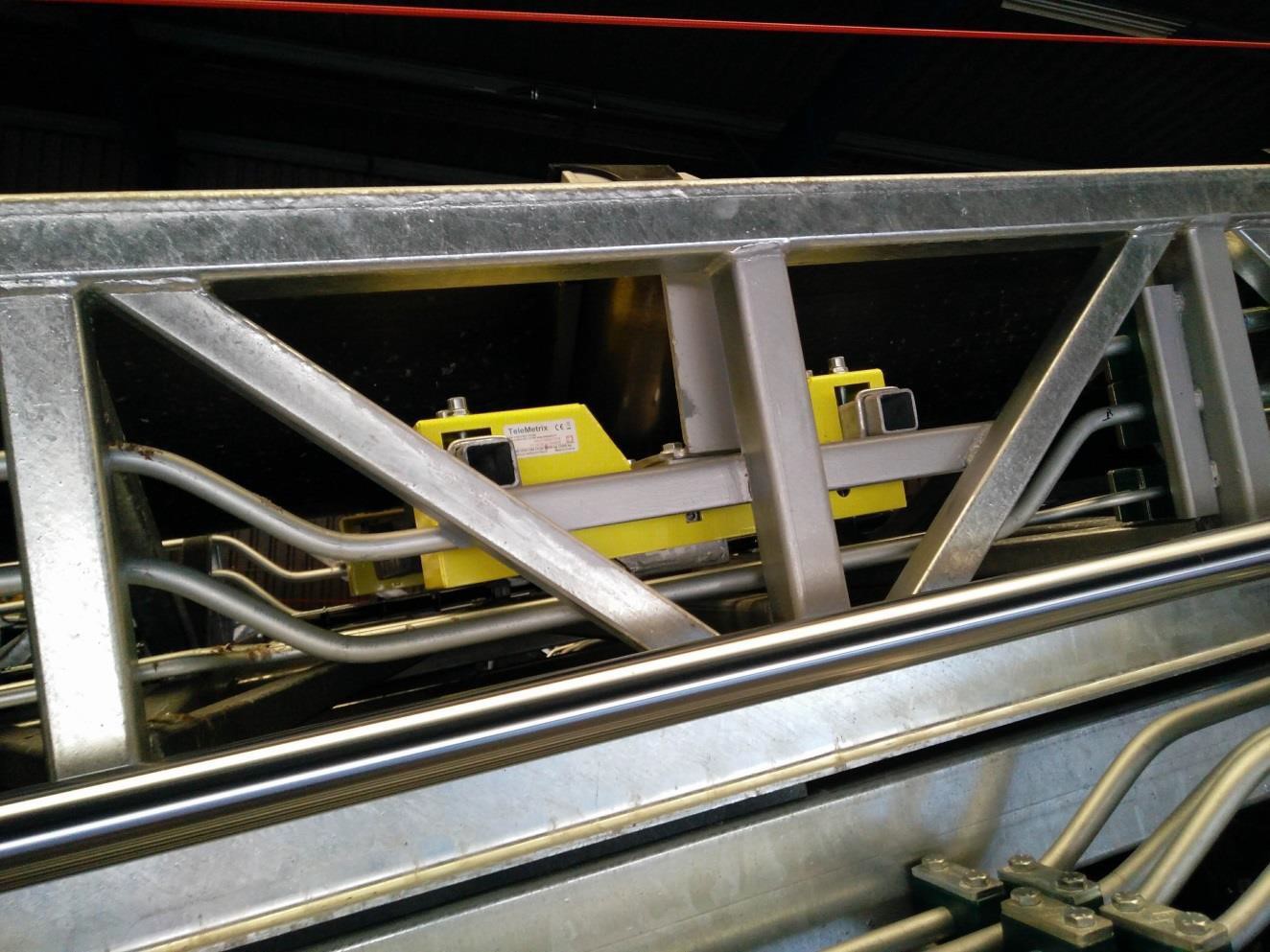

- Weighing scale

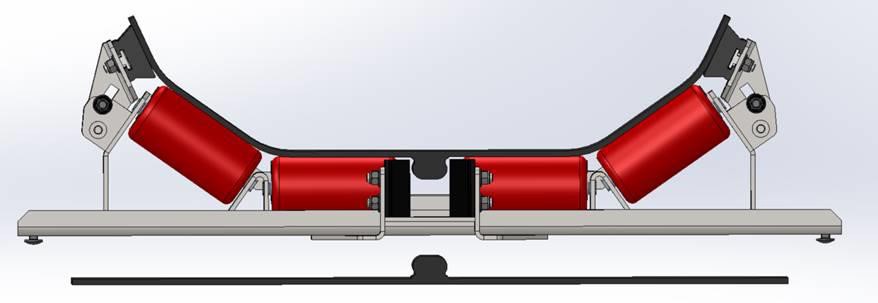

- Self-guided Belt

Controllable functions:

- Conveyor orientation

- Incline conveyor

- Conveyor translation

- Conveyor belt drive

- Automatic helmet opening

- Sealing reception hopper

- Hopper unclogging hammer

- Remote truck maneuver

- Engine speed adjustment

- Reset Toggle

- Honk

- Light

- No need an additional operator

- Automatic adjustment of the position of the shaft

- Manipulation of hatches effortlessly via hydraulic motor

- Hydraulic motor control via radio remote control

- Protects wagons (integrated force limiter)

- Reduces the risk of product spills on the road

- Facilitates conveyor maneuvering in folded position

- No need manual action by the operator

- Effortless handling via hydraulic cylinder

- Hydraulic cylinder control via radio control

- Reduces wagon unloading time

- Facilitates the flow of products in the hopper of the wagon

- Eliminates the risk of operator injury

- Hydraulic hammer control via radio control

- Protects HDPE impact buffer wagons

- Optimizes the throw curve of materials

- Centrelaze the flow of products

- Allows working in a narrower platform

- Eliminates the risk of driving an overloaded truck on public roads

- Saving of unloading time

- Instant flow

- Display of unloaded tonnes on the screen of the remote control

- Resetting the number of tonnes unloaded directly from the remote control